We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

One of the most critical components when designing a power supply for your equipment is a compatible transformer. If your equipment doesn’t receive the correct voltage, things can go downhill fast. Overheating components and equipment malfunctions are disasters waiting to happen. In industries that depend on precision—like medical, aerospace, and manufacturing—small power fluctuations can lead to costly downtime and failures.

A transformer does more than adjust voltage—it protects equipment, improves efficiency, and ensures reliability. Choosing the right one minimizes downtime, extends equipment life, and controls costs.

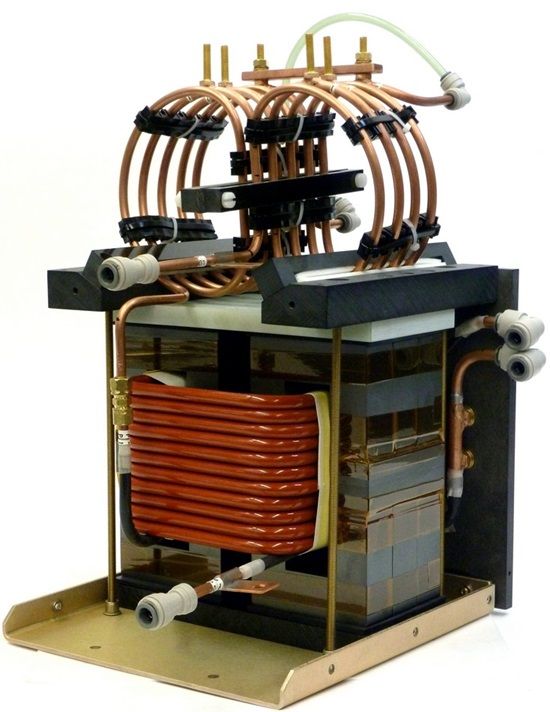

At its core, a transformer is just coils of wire wrapped around an Iron or ferrite core. Voltage is applied to one coil (the primary winding), creating a fluctuating magnetic field. That fluctuating field then transfers energy to the second coil (the secondary winding), “transforming” the applied voltage.

If the secondary coil has more windings than the primary winding, the voltage increases (step-up transformer). If it has fewer, the voltage decreases (step-down transformer). The frequency stays the same, but the transformer designer can vary the primary to secondary turns ratio to match what the system needs.

You’ll find transformers everywhere, keeping power stable and reliable:

Aerospace & Aviation – Powering radar, flight controls, and navigation systems.

Medical Equipment – Delivering stable voltage to MRI machines, surgical tools, and lab equipment.

Manufacturing & Automation – Preventing voltage fluctuations that could shut down assembly lines.

Renewable Energy – Converting power from wind and solar into usable electricity.

Different industries have very specific power needs. The wrong transformer can lead to wasted energy, equipment failures, or expensive downtime. The right one ensures efficiency, reliability, and long-term performance – which is why picking the right transformer isn’t just a technical decision. It’s a business-critical one.

A transformer is what keeps power stable and equipment running the way it should. But if the transformer isn’t a good match for the system, the consequences go beyond inefficiency. Poor voltage control leads to wasted energy, unstable performance, and in some cases, complete system failure.

When a transformer isn’t designed for the load it’s handling, energy gets lost as excess heat instead of useful power. That heat buildup isn’t just wasteful – it puts extra stress on the system. In industrial settings, even small inefficiencies add up. A factory running multiple misaligned transformers could be losing thousands of dollars in wasted electricity every year.

Unstable power is a slow killer. When voltage keeps shifting up and down, sensitive electronics start to wear out. Medical imaging machines, for example, require less than a 1% variation in voltage to function properly.

A transformer that can’t maintain steady output could cause distorted scans or unreliable test results. In manufacturing, unstable voltage can shut down automated systems or throw off precision equipment, leading to defects and downtime.

A transformer that isn’t rated for the job runs hot. And when it overheats, the entire system is in danger. Over time, excessive heat weakens insulation, damages wiring, and increases the chances of short circuits. In extreme cases, it can lead to catastrophic failures that take down an entire operation.

A large solar energy facility saw 30 transformer failures in six months. The cause? The transformers weren’t designed for the plant’s specific load requirements. The insulation inside them broke down under high temperatures, leading to repeated shutdowns. After switching to properly rated transformers, the failures stopped, and power output stabilized. Read the full case study here.

A well-designed transformer protects the system just as well as it powers it. In industries like healthcare, aerospace, and manufacturing, unreliable power isn’t just inconvenient – it’s a financial and operational risk. Choosing the right transformer ensures:

Consistent power flow to keep operations running without interruptions.

Lower maintenance costs by preventing overheating and equipment wear.

Longer lifespan for both the transformer and the equipment it powers.

The bottom line? A transformer might seem like a small part of a larger system, but when it’s the wrong one, the costs go far beyond just replacing a faulty component.

Not all transformers are created equal. While standard, off-shelf models work in some cases, many industries require precision power control that generic transformers can't provide. That's where custom transformers come in. They're designed to match specific voltage, current, and environmental demands, ensuring that equipment runs efficiently and safely.

Every system has unique power needs. Some equipment demands exact voltage with zero fluctuation, while others handle high loads and need specialized insulation to prevent overheating. A custom transformer matches these exact specifications, avoiding the risks of one-size-fits-all solutions.

In medical technology, aerospace, and automation, space matters. Standard transformers often prove too bulky or inefficient for tight spaces. Custom transformers fit specific size and weight limits without compromising power delivery.

Some environments push equipment to its limits. Systems might face extreme temperatures, constant vibration, or corrosive conditions where standard transformers fail. Custom-built units handle:

High heat and humidity in mining operations

Constant vibration in aerospace applications

Outdoor exposure in renewable energy system

Healthcare, aviation, and defense have strict regulations. Equipment must meet specific safety and performance standards. Custom transformers comply with these certifications from the start, preventing compliance issues and expensive fixes later.

A transformer isn't just another electrical component – it's the backbone of your power system. It regulates voltage, ensures equipment operates efficiently, and protects against costly failures. When chosen correctly, a transformer keeps power stable, extends equipment life, and reduces energy waste. But the wrong transformer leads to overheating, equipment malfunctions, and unplanned downtime – problems that cost thousands in repairs and lost productivity.

Transformer failures don't just stop one machine – they shut down entire operations. Manufacturing lines freeze, costing thousands per hour in lost production. Data centers crash, affecting countless users and damaging client trust. Hospitals face delayed procedures and compromised patient care. A properly matched transformer prevents these issues by maintaining reliable, stable power.

Poor transformer efficiency wastes power as heat, driving up electricity bills and straining cooling systems. In industrial settings, even small efficiency improvements save thousands annually. Better transformers minimize losses through improved design and materials, turning more input power into usable output instead of waste heat.

Power fluctuations kill equipment fast. High voltage burns out electronics. Low or unstable voltage makes systems work harder, wearing them out sooner. Motors fail early, circuit boards break down, and precision machines lose calibration. Quality transformers prevent these issues by delivering exact voltage levels without fluctuation.

Many industries face strict power regulations. Medical facilities need specific power quality for patient safety. Aerospace requires transformers that meet rigorous standards. Using the wrong transformer means failed inspections, regulatory violations, and expensive fixes.

While cheaper transformers save money upfront, long-term costs add up through frequent repairs, higher energy bills, damaged equipment, and production losses. For industries where power quality affects performance and safety, the right transformer is essential for operational success.

At Electronic Craftsmen, we specialize in transformers that match your exact needs. Our team works with you to understand your requirements, space limitations, and operating conditions. We'll help design a solution that keeps your systems running reliably for years to come.

Ready to improve your power system? Let's talk about how we can help make your equipment work better, last longer, and cost less to operate.

When you’re pricing your next custom transformer or inductor, it’s critical to get the specifications right, the first time. Our products and your applications demand precision…usually that involves some back-and-forth with engineers to gather all the information needed to generate an accurate quotation.

E Craftsmen offers a wide range of custom magnetics, each one with its own unique specification, so we created this one-page guide to use as a checklist to help you scope out all the details.

Our Quick Specifications Guide for Custom Magnetics will help you ensure that you’ve acquired all the pertinent details from electrical specifications to physical constraints and regulatory needs. Download the guide here and keep it handy to take along to your next design review meeting. We hope it’s a big help!

|

Designed primarily for Step-Down power supply for LED lighting devices, these products are Certified to both the U.S. and Canadian standards for General Purpose Component Transformers. |

The benefit to our customers is that the widely-recognized UL approval will simplify the acceptance of these compact transformers within their end-use fixtures by most safety certification organizations.

Because these parts are approved with this additional rating, they can be used in equipment with higher ambient temperatures.

With their low-profile height of only 1.31 inches and narrow width of 1.63 inches, these transformers are sure to fit the small-size requirements of today's LED fixtures.

We have custom transformers to meet your needs, plus we don't charge for quotes and designs, contact us!

Manufacturing is making a comeback in North America. But downward pressure persists from offshore commodity suppliers so time & cost-saving is the nature of the game.

R&D for new products with improved features, in smaller packages in increasingly shorter time frames is, for many, the only answer to declining revenues.

Why choose custom-made versus standard parts?

Logically, the first step for a designer to control material costs is to source standard, off-the-shelf components. The belief is that settling for a standard part will provide initial cost-savings vs. the superior choice of a custom-made part that will better suit the application. While this may be the case from a basic purchasing perspective, there are a number of design issues that may challenge that "price-only" choice over the long-term. (Not to mention that "catalogue" parts are rarely "on-the-shelf" anymore.)

Form and Fit: A Custom part expertly designed with consideration to dimensions, physical constraints and terminations will likely yield a much more effective solution rather than simply “settling” for a standard part that doesn't really fit. Unexpected time needed to rework a packaging layout can result in excessive design-cycle costs. Experienced magnetic designers have exposure to a wide range of materials and innovative methods to develop a part tailored to fit just right.

Function: Losses in a transformer or inductor due to ripple currents and harmonic content can cause unexpected over-heating. Weeks lost in waiting for delivery of a low-cost catalogue part followed by set-backs due to inadequate or even dangerous performance can put the development cycle of a new product into jeopardy.

Duty cycle: Expert attention given to intermittent operation duty cycle in a custom design generally results in a dramatically smaller, cooler and cost-effective part than originally estimated.

Expert Collaboration: Often, doing it yourself takes more time and leads to frustration. Working with a professional that is skillfully trained in the design of magnetics can offer invaluable insights and know-how that are just not available from that “order-taker” at the electrical distributor.

All in all, what appears to be short-term gain can result in long-term pain when it comes to procuring parts best suited to the application. Don’t just “settle”… Send us your specs and we'll give you a qualified quote! on a better design.

In response to a market need, E Craftsmen has developed a family of agency approved 347V Step-Down Autotransformers. This voltage is unique to Canadian commercial and industrial installations and represents the line-to-neutral phase of the standard 600V 3-phase power grid. Most of these requests come from the lighting industry and relate to the increasing popularity of LED lighting.

Typical world-wide primary voltage is in the range of 100 to 240V at 50 or 60Hz. As a result, a number of power-supply manufacturers have developed off-the-shelf devices that will accept any voltage between 100-240V (known as ‘universal input supplies”). This approach is adequate in many installations but typically in commercial and industrial sites, lighting is powered by 347V and these universal input power supplies are not capable of operating at this higher voltage.

Consequently, the installation requires that the 347V be converted or “stepped-down” to 220-240V in order to be connected to these power supplies. The most cost-effective method of stepping down from 347V is by use of an autotransformer. Most importantly, the autotransformer must be designed in such a way as to satisfy safety requirements for 347V input.

Power ratings include 50VA, 100VA and 240VA with efficiencies of 93% and up. The unique “Low Profile” form factor of these parts is ideal for fluorescent ballast retrofit and numerous other similar applications. Of course, there are numerous other ratings and sizes available that can be customized to specification…contact us for details!

More Information about the 347V

Star Trek would have us instantly teleporting across distance & space but until that becomes a reality, we must rely on planes, trains & automobiles (and occasionally boats) to get materials from suppliers to customers.

With over 60 years of experience in supplying our custom parts to customers throughout North America and across the oceans, we've encountered our share of "unfortunate events" with shipping. So here are a few things to think about in the pursuit of getting your parts on time, intact, and at a somewhat reasonable cost.

OK, so we’ve been a little hard on some of the big carriers but please know that we use many of them daily because they generally get the job done...and we know the ups & downs. The main point is that with just a little preparation in advance, we’ll get your parts to you safe & sound, on-time and at a cost that won’t empty your wallet.