We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

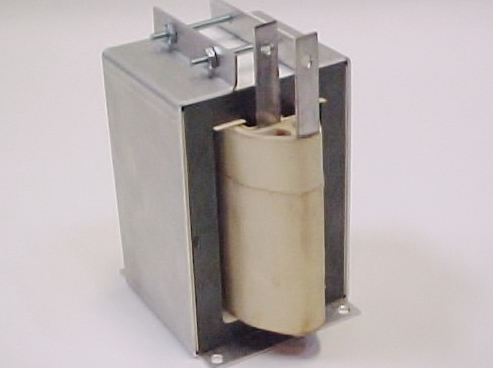

Whether you need a custom inductor solution or a straightforward build to print, our Ontario-based team offers advanced design expertise and proven manufacturing know-how. We deliver reliable and innovative inductors that meet even the most demanding specifications. Each custom inductor is engineered to function correctly the first time and is backed by our 5-year warranty, providing you with peace of mind.

Do you need a bit more information before sending us your inductor specs? Learn more about our Capabilities or the Importance of Identifying Harmonic Content.

Inductance: uH to H

Currents to 1100A nominal, AC or DC

AC Ripple Current and Harmonics accommodated to specification

Working Voltage up to 12kV (depending on frequency); multiple stages possible for higher outputs

Frequency: DC to 500kHz (typical)

Temperature Class to 220C (155C / Class F typical)

Weight: 0.06 oz / 1g to 550 lbs / 250kg

Multiple taps as required

Dielectric Strength (hipot) to 30kVac or 20kVdc

Parts can be vacuum varnished or molded with a variety of hard or soft encapsulant materials with thermal conductivity.

Wire sizes from 1-45 AWG or Copper Foil to 0.050in thick (in multiple layers for higher current); Litz wire for higher frequency

Regulation to specification

Manufactured using all known state-of-the-art magnetic core materials, including but not limited to electrical grade steel laminations, ferrites & powdered iron, nickel-iron alloy, iron amorphous metal strip-wound cores, nanocrystalline cores, and small toroids.

Antifungal and non-nutrient coatings are available

Corrosion-resistant coatings & platings available

Standard or custom terminations & leads

Mounting Configurations: pcb-mount (horizontal or vertical), custom or standard brackets, or stacked configurations

Designed to meet CSA & UL (safety) or MIL PRF 27 (aerospace/military) requirements upon request

MIL PRF 27 Grade 5 & 6 encapsulation available

Our custom three-phase inductors are used in applications including aviation, power conditioning, renewable energy power conversion, and high-power battery charging, to name a few.

Designs may incorporate foil and high-temperature windings, strip-wound amorphous metal, ferrite or high-grade steel cores. Dimensions and mountings are tailored to suit your specific needs. Inductors can also be incorporated into the primary winding of a transformer to save both cost and space.

High Frequency & Switch Mode Inductors

.jpg)

DC & AC Inductors, Chokes & Reactors

We build custom applications for many industries including the ones with tough, demanding Aviation and Marine environments. We know special consideration must be given to vibration, moisture, weight, contamination and qualification. Unique winding configurations, high-efficiency cores, high-strength and non-nutrient encapsulants.

We work closely with you and your technical team to develop custom inductor solutions that meet your most complex requirements.

What types of custom inductors do you manufacture?

We manufacture custom inductors, reactors, and chokes using a wide range of state-of-the-art magnetic core materials, including electrical grade steel laminations, ferrites, powdered iron, nickel-iron alloy, amorphous metal strip-wound cores, and nanocrystalline cores. Our designs can be tailored for DC or AC applications and are available in various mounting configurations to suit your needs.

Which industries and applications use your custom inductors?

Our custom three-phase inductors are used in applications such as aviation, power conditioning, renewable energy power conversion, and high-power battery charging. We also support OEM, commercial, and industrial clients across Canada with solutions for high-frequency and switch-mode applications.

Can your inductors meet specific safety and certification standards?

Yes, our inductors can be designed to meet CSA and UL safety requirements or MIL PRF 27 for aerospace and military applications. We also offer encapsulation and a variety of coatings for additional protection and compliance.

What are the advantages of choosing a custom inductor over a standard part?

Custom inductors are engineered to match your exact specifications, including dimensions, mounting, electrical performance, and duty cycle. This results in parts that offer better fit, improved efficiency, and reliability compared to off-the-shelf options, which may not always be readily available or suitable for your application.

What information should I provide to request a quote for a custom inductor?

To receive an accurate quote, please provide details such as required inductance, current rating, voltage, frequency, preferred core material, mounting configuration, and any special requirements for coatings or certifications. Sharing your application details or schematic can help us deliver the best solution for your needs.