We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

Power supply problems can arise in many ways. When hospital diagnostic equipment produces a blurry image; or train systems malfunction, four key power supply design components are usually involved: inductors, chokes, reactors, and filters. Each one controls power differently and selecting the wrong components during power supply design risks complete equipment failure.

In high reliability settings such as aerospace and medical facilities, power supply issues can cause equipment overheating, incorrect readings, or equipment that stops working completely. As an example, hospital imaging machines need special filters for clear imaging. A second example can be train systems that need powerful reactors to handle massive electrical loads. Off the shelf components often can't handle these tough jobs.

Different equipment needs different power solutions. Medical equipment must have clean, steady power. Aircraft systems need reliable power for safety. Factory machines need stable power to keep running. When basic components aren't enough, custom-designed solutions protect this critical equipment from failure.

This guide explains what makes each power component different and when you need custom versions. Whether you work with simple equipment or complex systems, knowing these differences helps avoid costly mistakes.

An inductor is used to introduce Inductance (L) into an electric circuit, preventing sudden changes in current flow. When a current (i) flows through the coil of an inductor, it develops a voltage potential (e) across its contact leads. This process allows the inductor to temporarily store electrical energy in a magnetic field within the core and around the coil. The core enhances the inductance and efficiency by concentrating magnetic flux lines within a closed magnetic path structure, helping to stabilize power inconsistencies.

An inductor's performance is determined by factors such as core material, wire gauge, air gap, and the number of turns in the coil. Most inductors use iron, ferrite, or air cores, each offering different characteristics for specific applications. The number of turns and the core type influence the strength of the magnetic field, directly affecting how the inductor functions within a circuit. For a deeper look at how inductors work, this technical guide from Bel Fuse covers their role alongside chokes, reactors, and filters.

You'll find inductors hard at work in many important industrial systems, such as:

In solar and wind power installations, they help convert unstable power into smooth, usable electricity.

Inside factory robots and automated systems, they keep power steady, so machines run smoothly.

In medical imaging equipment, they filter out electrical noise that could blur important diagnostic images.

While standard inductors work for basic jobs, you need a custom solution when your system requires a specific voltage or frequency range, when you're working with tight spaces or weight limits, or when your equipment operates in tough conditions like extreme heat or vibration.

Getting the right inductor, especially when you need a custom one, isn't just about making things work. It's about making them work reliably and efficiently for years to come. That's why engineers spend so much time choosing exactly the right inductor for each job.

A Choke is an Inductor type with or without a ferromagnetic core, used to block, hence “choke”, alternating current (AC) in a circuit by limiting the rate of change over a specified frequency range, while allowing passage of lower frequency AC or direct current (DC). This effect is often used in power supply circuits where the public AC mains (line) supply has to be converted to a DC supply suitable for powering electronic circuits.

In critical equipment like medical scanners or aircraft systems, this type of inductor protects against power disturbances that could cause equipment damage or system failures.

There are two main types of chokes, each designed to handle different forms of interference.

Common-mode chokes target interference affecting multiple power lines at once. Medical imaging systems need these to maintain diagnostic accuracy. Aircraft navigation depends on them for reliable signal quality. A failure in common-mode filtering could lead to blurred scans or corrupted flight data. These components are especially crucial in environments with high external interference.

Differential-mode chokes handle interference between individual power lines within a system. Manufacturing facilities rely on them to protect automated equipment from internal power fluctuations. Without proper filtering, voltage spikes could damage expensive machinery or halt production entirely. In industrial settings, these chokes often prevent costly downtime and equipment damage.

Chokes are widely used in hospitals, aircraft, factories, and data centers, where clean power is a necessity. In medical applications, chokes help maintain diagnostic accuracy, ensuring reliable imaging results. Aerospace electronics depend on them to keep communication and navigation systems free from interference. In industrial automation, they prevent voltage fluctuations from disrupting robotic precision and production efficiency.

While standard chokes work in many applications, some industries require specialized designs. Extreme electrical noise, unique frequency requirements, or strict regulatory compliance may demand custom chokes tailored to specific operating conditions. In these cases, engineered solutions provide the precise filtering needed to ensure uninterrupted performance and system longevity.

Reactors are large electrical reactors that keep industrial power systems stable and protected. Unlike regular inductors, these parts handle huge electrical loads, stopping power surges that can damage costly machines or shut down entire operations.

The science behind reactors is straightforward but critical. They create controlled electrical impedance in power circuits, acting as a barrier against voltage spikes and harmonic distortion. Without this protection, power fluctuations could overheat motors, trigger system failures, or cause widespread equipment damage.

Line Reactors guard industrial systems against power surges. When voltage suddenly spikes, these reactors absorb the excess power that would otherwise destroy factory equipment, HVAC systems, or motor drives.

Harmonic Reactors tackle power quality issues caused by modern electronic equipment. Variable frequency drives (VFDs) and uninterruptible power supplies can create electrical noise that strains systems. These reactors clean up the power, keeping equipment running within safety standards.

Load Reactors protect motors from electrical stress. In mining operations, railways, and industrial automation, motors need consistent power to function reliably. These reactors prevent overheating and control startup current surges.

Reactors play a vital role in power plants, transportation systems, manufacturing facilities, and renewable energy infrastructure – anywhere stable power distribution is necessary. In high-voltage substations, reactors help prevent electrical overloads that could cause grid instability. In electric train systems, they regulate power flow to traction motors, ensuring safe and efficient operation.

While standard reactors work in many applications, some systems require custom-engineered solutions to handle specific voltage levels, frequency conditions, or environmental constraints. Reactors designed for extreme temperatures, high-vibration environments, or unique electrical loads provide greater reliability and efficiency compared to off-the-shelf models.

Power filters remove unwanted electrical noise and interference from power systems. Unlike basic surge protectors, these components provide sophisticated frequency control, ensuring equipment gets clean, stable power. This filtering capability is crucial in medical facilities, electronics manufacturing, and communications systems where signal quality directly affects performance.

Filters use specific combinations of electrical components to control which frequencies pass through. Through careful design of inductors and capacitors, they create paths that trap interference while allowing desired power signals to flow. This selective blocking prevents both electromagnetic (EMI) and radio frequency (RFI) interference from disrupting sensitive equipment.

Different types of filters handle different jobs:

Low-pass filters block high-frequency interference while allowing lower frequencies through. These protect power supplies and sensitive electronics from fast-changing electrical noise that could cause malfunctions.

High-pass filters do the opposite - they block low-frequency interference while allowing high-frequency signals to pass

Bandpass filters are more selective, allowing only specific frequency ranges to pass through. Medical imaging equipment relies on these for precise signal control and clear diagnostic results.

EMI filters handle a specific challenge: electromagnetic interference. They shield sensitive electronic systems from the electrical noise generated by motors, power lines, and wireless devices. In industrial settings, where heavy machinery operates near delicate control systems, EMI filtering prevents equipment failures and data corruption.

Filters protect essential equipment in some of the toughest conditions. In hospitals, they keep power steady for accurate test results – one small power problem could affect patient care. Telecommunications centers rely on them to keep data flowing smoothly through their delicate communication systems. Without proper filtering, important messages could be lost.

Manufacturing facilities need filters to protect precision machinery. Modern factory floors run on complex automated systems that depend on clean, stable power. Even minor electrical interference can throw off calibration or cause expensive production errors. Research laboratories face similar challenges, where delicate scientific instruments need pristine power conditions for accurate measurements.

While standard filters handle common interference problems, many specialized applications demand custom solutions. High-tech medical equipment might need filters designed for specific frequency ranges. Data centers often require filters that can handle unusual power loads or meet strict performance standards. Manufacturing equipment might face harsh electrical environments that overwhelm basic filters.

Custom-engineered filters become essential when standard components can't meet these challenges. Whether it's dealing with high-frequency noise, meeting strict regulatory requirements, or handling unusual power conditions, these specialized filters ensure reliable operation where standard units would fail. In critical applications where clean power directly affects performance and safety, custom filtering solutions protect both equipment and operations.

Choosing the right electrical component requires matching your system's exact needs. Whether you need an inductor, choke, reactor, or filter, getting it wrong can lead to equipment damage or system failure.

Key Selection Factors:

Power and Frequency Needs: Components must handle your specific power levels and electrical signals

Environmental Requirements: Consider heat, vibration, and moisture resistance needs

Load Capacity: Ensure components can handle your system's full electrical load

Safety Standards: Match industry-specific requirements for medical, aerospace, or industrial use

Think of custom components as an investment in reliability. While they might cost more upfront, they can prevent expensive problems down the road. For critical systems where failure isn't an option, custom-engineered solutions often provide the best long-term value.

From medical equipment to high-speed trains, the right power components keep critical systems running safely. Whether you need an inductor, choke, reactor, or filter, choosing the wrong one risks expensive repairs or dangerous failures. Custom solutions provide the reliability these systems need to run safely and meet all requirements.

Ready to find the right solution? Let's discuss your specific needs.

One of the most critical components when designing a power supply for your equipment is a compatible transformer. If your equipment doesn’t receive the correct voltage, things can go downhill fast. Overheating components and equipment malfunctions are disasters waiting to happen. In industries that depend on precision—like medical, aerospace, and manufacturing—small power fluctuations can lead to costly downtime and failures.

A transformer does more than adjust voltage—it protects equipment, improves efficiency, and ensures reliability. Choosing the right one minimizes downtime, extends equipment life, and controls costs.

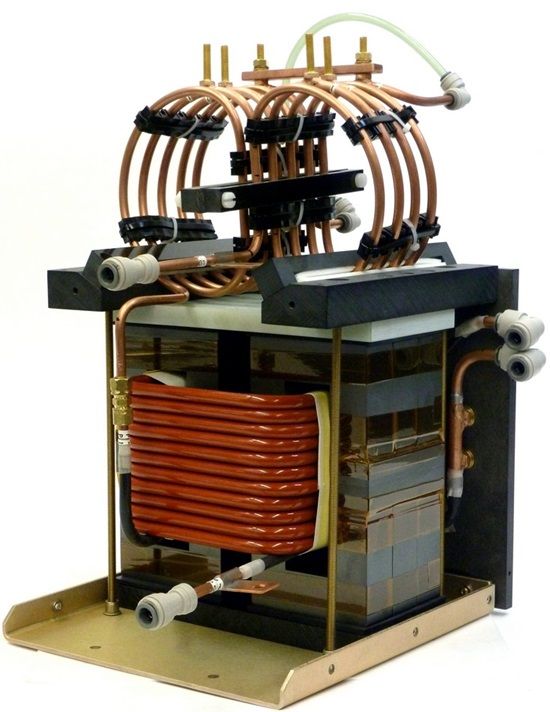

At its core, a transformer is just coils of wire wrapped around an Iron or ferrite core. Voltage is applied to one coil (the primary winding), creating a fluctuating magnetic field. That fluctuating field then transfers energy to the second coil (the secondary winding), “transforming” the applied voltage.

If the secondary coil has more windings than the primary winding, the voltage increases (step-up transformer). If it has fewer, the voltage decreases (step-down transformer). The frequency stays the same, but the transformer designer can vary the primary to secondary turns ratio to match what the system needs.

You’ll find transformers everywhere, keeping power stable and reliable:

Aerospace & Aviation – Powering radar, flight controls, and navigation systems.

Medical Equipment – Delivering stable voltage to MRI machines, surgical tools, and lab equipment.

Manufacturing & Automation – Preventing voltage fluctuations that could shut down assembly lines.

Renewable Energy – Converting power from wind and solar into usable electricity.

Different industries have very specific power needs. The wrong transformer can lead to wasted energy, equipment failures, or expensive downtime. The right one ensures efficiency, reliability, and long-term performance – which is why picking the right transformer isn’t just a technical decision. It’s a business-critical one.

A transformer is what keeps power stable and equipment running the way it should. But if the transformer isn’t a good match for the system, the consequences go beyond inefficiency. Poor voltage control leads to wasted energy, unstable performance, and in some cases, complete system failure.

When a transformer isn’t designed for the load it’s handling, energy gets lost as excess heat instead of useful power. That heat buildup isn’t just wasteful – it puts extra stress on the system. In industrial settings, even small inefficiencies add up. A factory running multiple misaligned transformers could be losing thousands of dollars in wasted electricity every year.

Unstable power is a slow killer. When voltage keeps shifting up and down, sensitive electronics start to wear out. Medical imaging machines, for example, require less than a 1% variation in voltage to function properly.

A transformer that can’t maintain steady output could cause distorted scans or unreliable test results. In manufacturing, unstable voltage can shut down automated systems or throw off precision equipment, leading to defects and downtime.

A transformer that isn’t rated for the job runs hot. And when it overheats, the entire system is in danger. Over time, excessive heat weakens insulation, damages wiring, and increases the chances of short circuits. In extreme cases, it can lead to catastrophic failures that take down an entire operation.

A large solar energy facility saw 30 transformer failures in six months. The cause? The transformers weren’t designed for the plant’s specific load requirements. The insulation inside them broke down under high temperatures, leading to repeated shutdowns. After switching to properly rated transformers, the failures stopped, and power output stabilized. Read the full case study here.

A well-designed transformer protects the system just as well as it powers it. In industries like healthcare, aerospace, and manufacturing, unreliable power isn’t just inconvenient – it’s a financial and operational risk. Choosing the right transformer ensures:

Consistent power flow to keep operations running without interruptions.

Lower maintenance costs by preventing overheating and equipment wear.

Longer lifespan for both the transformer and the equipment it powers.

The bottom line? A transformer might seem like a small part of a larger system, but when it’s the wrong one, the costs go far beyond just replacing a faulty component.

Not all transformers are created equal. While standard, off-shelf models work in some cases, many industries require precision power control that generic transformers can't provide. That's where custom transformers come in. They're designed to match specific voltage, current, and environmental demands, ensuring that equipment runs efficiently and safely.

Every system has unique power needs. Some equipment demands exact voltage with zero fluctuation, while others handle high loads and need specialized insulation to prevent overheating. A custom transformer matches these exact specifications, avoiding the risks of one-size-fits-all solutions.

In medical technology, aerospace, and automation, space matters. Standard transformers often prove too bulky or inefficient for tight spaces. Custom transformers fit specific size and weight limits without compromising power delivery.

Some environments push equipment to its limits. Systems might face extreme temperatures, constant vibration, or corrosive conditions where standard transformers fail. Custom-built units handle:

High heat and humidity in mining operations

Constant vibration in aerospace applications

Outdoor exposure in renewable energy system

Healthcare, aviation, and defense have strict regulations. Equipment must meet specific safety and performance standards. Custom transformers comply with these certifications from the start, preventing compliance issues and expensive fixes later.

A transformer isn't just another electrical component – it's the backbone of your power system. It regulates voltage, ensures equipment operates efficiently, and protects against costly failures. When chosen correctly, a transformer keeps power stable, extends equipment life, and reduces energy waste. But the wrong transformer leads to overheating, equipment malfunctions, and unplanned downtime – problems that cost thousands in repairs and lost productivity.

Transformer failures don't just stop one machine – they shut down entire operations. Manufacturing lines freeze, costing thousands per hour in lost production. Data centers crash, affecting countless users and damaging client trust. Hospitals face delayed procedures and compromised patient care. A properly matched transformer prevents these issues by maintaining reliable, stable power.

Poor transformer efficiency wastes power as heat, driving up electricity bills and straining cooling systems. In industrial settings, even small efficiency improvements save thousands annually. Better transformers minimize losses through improved design and materials, turning more input power into usable output instead of waste heat.

Power fluctuations kill equipment fast. High voltage burns out electronics. Low or unstable voltage makes systems work harder, wearing them out sooner. Motors fail early, circuit boards break down, and precision machines lose calibration. Quality transformers prevent these issues by delivering exact voltage levels without fluctuation.

Many industries face strict power regulations. Medical facilities need specific power quality for patient safety. Aerospace requires transformers that meet rigorous standards. Using the wrong transformer means failed inspections, regulatory violations, and expensive fixes.

While cheaper transformers save money upfront, long-term costs add up through frequent repairs, higher energy bills, damaged equipment, and production losses. For industries where power quality affects performance and safety, the right transformer is essential for operational success.

At Electronic Craftsmen, we specialize in transformers that match your exact needs. Our team works with you to understand your requirements, space limitations, and operating conditions. We'll help design a solution that keeps your systems running reliably for years to come.

Ready to improve your power system? Let's talk about how we can help make your equipment work better, last longer, and cost less to operate.

Manufacturing is making a comeback in North America. But downward pressure persists from offshore commodity suppliers so time & cost-saving is the nature of the game.

R&D for new products with improved features, in smaller packages in increasingly shorter time frames is, for many, the only answer to declining revenues.

Why choose custom-made versus standard parts?

Logically, the first step for a designer to control material costs is to source standard, off-the-shelf components. The belief is that settling for a standard part will provide initial cost-savings vs. the superior choice of a custom-made part that will better suit the application. While this may be the case from a basic purchasing perspective, there are a number of design issues that may challenge that "price-only" choice over the long-term. (Not to mention that "catalogue" parts are rarely "on-the-shelf" anymore.)

Form and Fit: A Custom part expertly designed with consideration to dimensions, physical constraints and terminations will likely yield a much more effective solution rather than simply “settling” for a standard part that doesn't really fit. Unexpected time needed to rework a packaging layout can result in excessive design-cycle costs. Experienced magnetic designers have exposure to a wide range of materials and innovative methods to develop a part tailored to fit just right.

Function: Losses in a transformer or inductor due to ripple currents and harmonic content can cause unexpected over-heating. Weeks lost in waiting for delivery of a low-cost catalogue part followed by set-backs due to inadequate or even dangerous performance can put the development cycle of a new product into jeopardy.

Duty cycle: Expert attention given to intermittent operation duty cycle in a custom design generally results in a dramatically smaller, cooler and cost-effective part than originally estimated.

Expert Collaboration: Often, doing it yourself takes more time and leads to frustration. Working with a professional that is skillfully trained in the design of magnetics can offer invaluable insights and know-how that are just not available from that “order-taker” at the electrical distributor.

All in all, what appears to be short-term gain can result in long-term pain when it comes to procuring parts best suited to the application. Don’t just “settle”… Send us your specs and we'll give you a qualified quote! on a better design.